The difference between galvanized steel structure warehouses and painted steel structure warehouses

The difference between galvanized steel structure warehouses and painted steel structure warehouses lies primarily in their surface treatment processes, which directly impact durability, corrosion resistance, maintenance costs, and aesthetics. Below is a detailed comparison across key aspects:

1. Surface Treatment Process

Galvanized Steel Structure

Process: Steel components are immersed in molten zinc (hot-dip galvanizing) or electroplated with a thin zinc layer. The zinc reacts with air to form a protective zinc oxide layer, creating a self-healing barrier against corrosion.

Coating Thickness: Typically 50–275 μm (microns), depending on the environment and standards (e.g., ASTM A123 for hot-dip galvanizing).

Painted Steel Structure

Process: Steel surfaces are cleaned (e.g., sandblasting, degreasing) and coated with 1–3 layers of paint (primer + intermediate + topcoat). Common paint types include epoxy, polyurethane, or acrylic.

Coating Thickness: Usually 80–200 μm total (combined layers), but thinner than galvanizing.

2. Corrosion Resistance

Galvanized Steel

Superior Protection: Zinc sacrificially corrodes before steel, even if the coating is scratched. Ideal for harsh environments (coastal areas, high humidity, chemical exposure).

Longevity: 20–50 years or more with minimal maintenance, depending on zinc thickness and environment.

Painted Steel

Moderate Protection: Paint acts as a physical barrier but relies on intact layers. Scratches or peeling expose steel to rust. Performance degrades faster in wet, salty, or industrial-polluted areas.

Longevity: 10–20 years, requiring regular repainting (every 5–10 years) to maintain protection.

3. Maintenance Requirements

Galvanized Steel

Low Maintenance: Rarely needs repainting. Occasional cleaning (e.g., removing dirt or mild stains) suffices.

Cost Efficiency: Lower long-term costs due to minimal upkeep.

Painted Steel

High Maintenance: Requires periodic inspection and repainting to address peeling, fading, or damage. Neglect leads to rust and structural degradation.

Cost Efficiency: Higher long-term costs due to repainting labor and materials.

4. Aesthetics & Appearance

Galvanized Steel

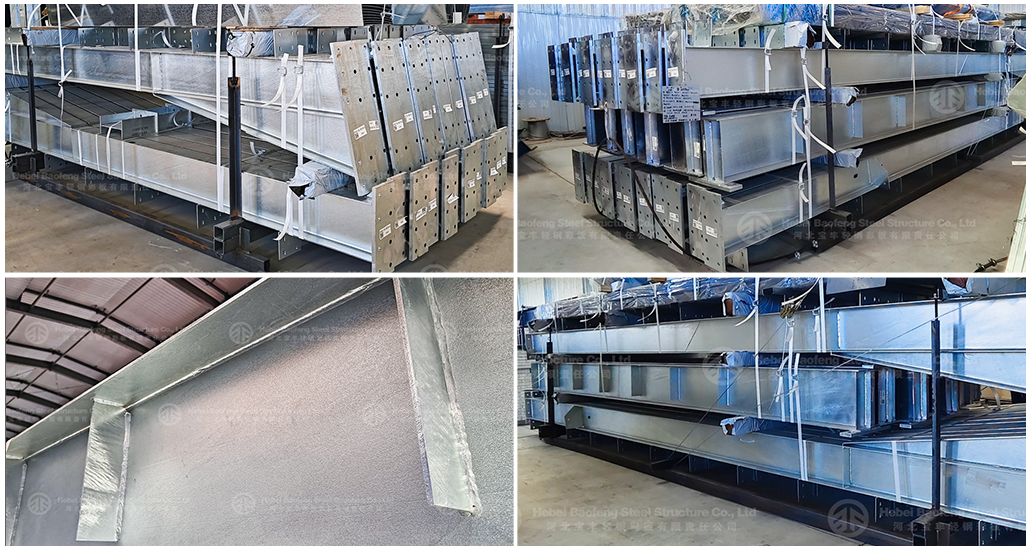

Industrial Look: Natural silver-gray finish. Can be left exposed for a utilitarian aesthetic or powder-coated/painted later for customization.

Color Options: Limited unless post-painting is applied (additional cost).

Painted Steel

Customizable Appearance: Available in various colors and finishes (matte, glossy, textured) to match architectural or branding needs.

Visual Appeal: Preferred for projects requiring specific colors (e.g., corporate branding, urban warehouses).

5. Cost Comparison

Initial Investment

Galvanized Steel: Higher upfront cost (zinc coating and hot-dip galvanizing process are more expensive than painting).

Painted Steel: Lower initial cost (simpler coating process and cheaper materials).

Long-Term Cost

Galvanized Steel: More cost-effective over 20+ years due to minimal maintenance and longer lifespan.

Painted Steel: Higher cumulative cost from repainting and potential repairs.

6. Environmental & Sustainability Factors

Galvanized Steel

Recyclability: Zinc and steel are 100% recyclable. The galvanizing process has a lower carbon footprint over the structure’s lifespan.

Eco-Friendly: No need for frequent repaints reduces waste and pollution.

Painted Steel

Paint Waste: Paint residues and solvents during application/repainting can harm the environment if not managed properly.

Carbon Footprint: Frequent repainting increases resource consumption and emissions.

7. Application Scenarios

Galvanized Steel Warehouses

Ideal For: Coastal regions, chemical plants, high-humidity areas, long-term projects, or warehouses storing corrosive materials (e.g., fertilizers, salt).

Examples: Cold storage facilities, port logistics hubs, industrial factories.

Painted Steel Warehouses

Ideal For: Dry climates, urban areas with mild weather, short-to-medium-term projects, or when aesthetics are a priority (e.g., showrooms, offices, retail spaces).

Examples: Temporary warehouses, small businesses, agricultural storage.

Conclusion

Choose Galvanized Steel if you prioritize durability, low maintenance, and long-term cost savings, especially in corrosive environments.

Choose Painted Steel if you need custom colors, lower initial costs, or operate in a dry, mild climate with regular maintenance access.

For projects requiring both aesthetics and durability, a hybrid approach (galvanizing first, then painting) is also common—it combines zinc’s corrosion resistance with paint’s visual appeal.

Categorias

último blog

Tag

© direito autoral: 2026 Hebei Baofeng Steel Structure CO.,LTD Todos os direitos reservados.

IPv6 rede suportada